Submersible Solenoid Valves

Marotta Controls is the leader in submersible solenoid valves. These are ideal for use in chilled water systems because their design allows them to be completely submerged without losing any performance. This means water flow can be controlled with precision in tighter spaces where mounting of external valves and piping would be difficult or impossible. Built to military-grade specifications, these valves are capable of operating in pressures of up to 400 psig.

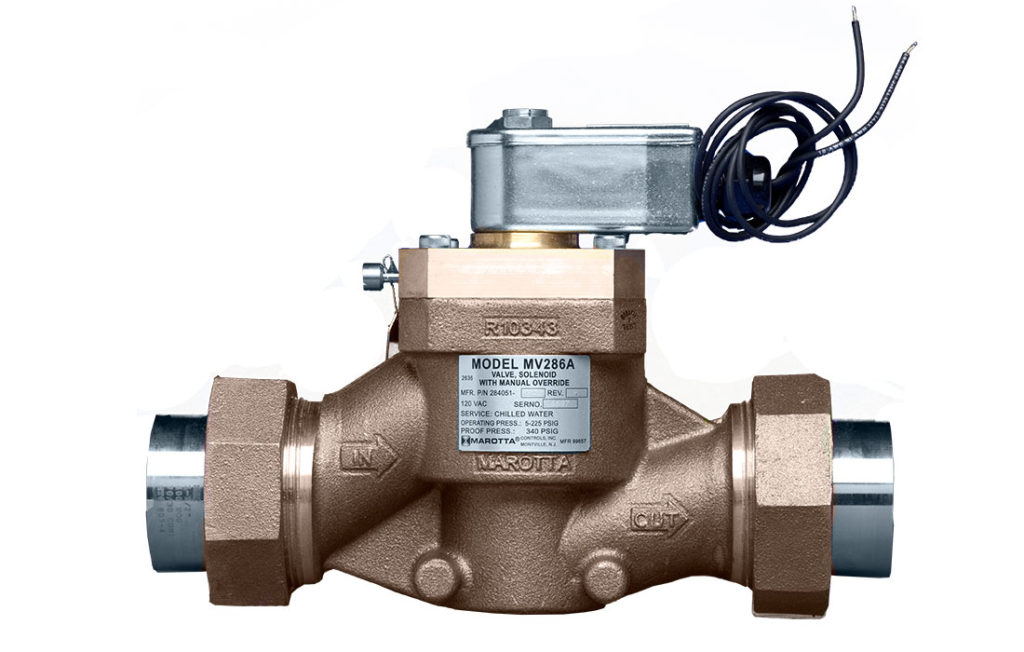

The MV286A Series cold water valves were developed to provide reliable control for air conditioning chilled water systems. This innovative design features a durable one-piece polypropylene poppet which provides improved performance, long-term reliability and ease of maintenance. A manual override is provided in case of a power failure or for manual operation.

Our range of chilled water valves deliver exceptional durability and reliability when compared to other manufacturers’. This is due in no small part to the strict quality controls we implement throughout our processes. Like everything else we manufacture, these chilled water control valves are made to adhere to the highest military standards and requirements. These valves are ideal for use in industrial applications in which water intrusion resistance is essential.

Our extensive in-house capabilities in engineering, design, analysis, manufacturing and testing ensure these submersible valves will stand up to the harshest conditions and perform at the highest levels.

- Fuel Oil Service

- Pneumatic Service

- Turbine Bleed Air Controls

- Propulsion Systems

- Flask Isolation

- Fire Suppression Systems

- Power Generation Systems

- Maneuverability Controls

MV286

These submersible Solenoid Valves meet the 2-way chilled water valve requirements of MIL-R-16743. They are supplied with the MIL-F-1183 bronze silver-brazed union ends. These are also available with copper nickel union ends for quick installation, or other materials of your choice. Units are also suitable for hydraulic and pneumatic fluids as well as light oils operating up to 400 psig.

Key Benefits of Submersible Solenoid Valves

- Water Intrusion Protection: Engineered to meet MIL-STD-108E standards for splashproof and submersible operation, Marotta’s valves ensure consistent performance in the harshest environments.

- Polypropylene Poppet Design: With their durable, one-piece poppet, these valves offer bubble-tight sealing, improved performance and a longer lifecycle that reduces downtime and maintenance costs.

- Pressure Versatility: Capable of operating under pressures as low as 3 psid and as high as 400 psig, these valves provide flexibility across a wide range of applications.

- Manual Override: In the event of power failure, these valves can be operated by hand to ensure ease of use in critical operations.

- Ease of Installation: Equipped with MIL-F-1183 silver-brazed union ends, these offer quick and secure installation that saves time and labor.

- Material Durability: These provide resistance to corrosion and wear, thanks to their cast aluminum bronze body as well as 300/400 series stainless steel trim and propylene seals.

- Versatile Operation: These are suited for chilled water, hydraulic fluids, light oils and pneumatic applications in temperatures ranging from -20 degrees Fahrenheit to 160 degrees Fahrenheit.

Fill out the form below to download MV286

Splashproof & Submersible

Marotta has engineered a solution to prevent water intrusion into the solenoid. This new technology meets the requirements of MIL-STD-108E for splash-proof and for submersible applications.

- Sizes available from 3/8″ to 2″, 2-way normally closed/normally open

- Polypropylene poppet for long life and bubble tight sealing

- Meets MIL-S-901 shock and MIL-167 vibration requirements

- Operates with pressure differentials as low as 3 psid

- Can withstand differential pressure across the poppet as high as 400 psig

- Available with Intelligent Fluid Control Electronics for distributed system control

To learn more about these products, download the datasheets or get in touch with us today.