DC Brushless Motors

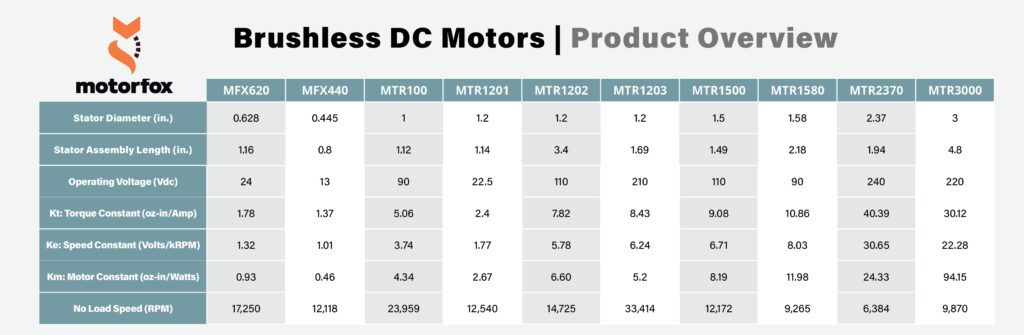

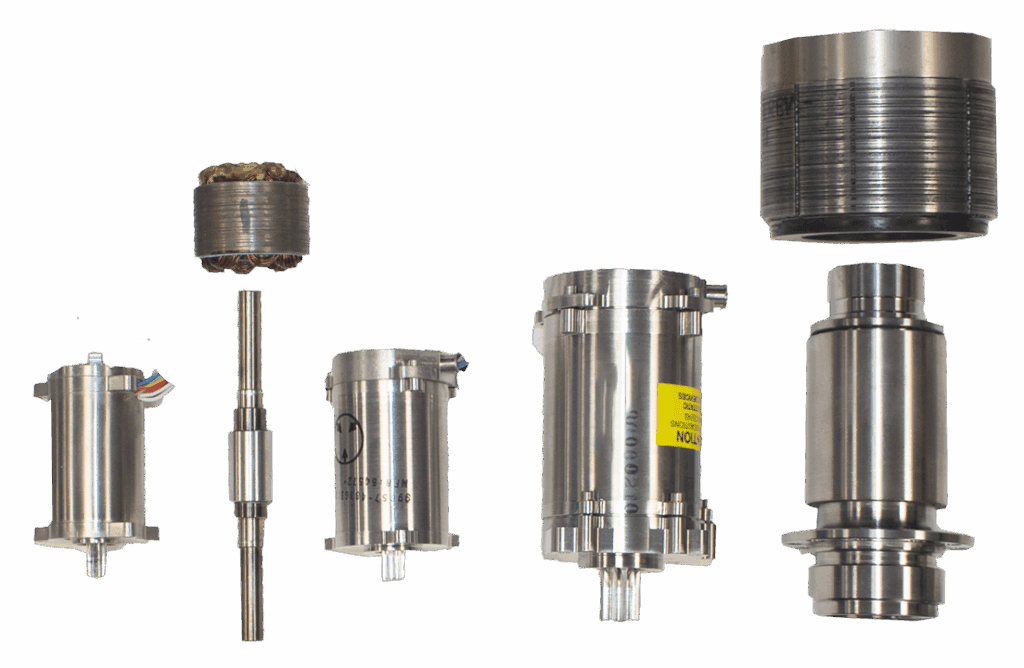

Marotta designed and qualified its first brushless DC motor in 2014 and has since designed a family of motors for actuation solutions in demanding aerospace and defense applications. In 2024, Marotta introduced its latest product line, Motorfox. Based in Minnesota, Motorfox is a 10,000 sq. ft. facility and represents the third Marotta operating site. Motorfox is capable of designing, developing, qualifying and manufacturing high-performance DC-Brushless motors for a wide range of aerospace and defense applications. Our precision brushless DC motors are currently available with lamination stack diameters from 0.4″ to 3.0″ and continue to increase in size.

Standard motors can be customized to customer specific mounting requirements, output shaft configurations, gearheads, and various commutation sensors. Motors are designed to RTCA-DO-160 or MIL-STD-810 and MIL-STD-461 requirements and adherence to FAR, DFAR or other government or regulatory agency requirements.

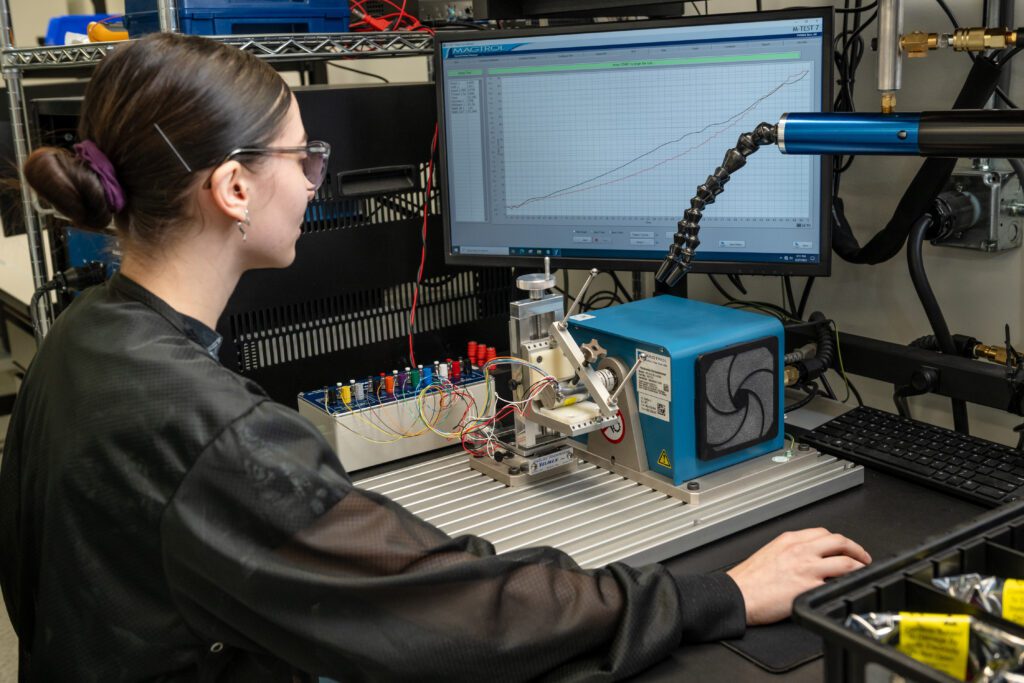

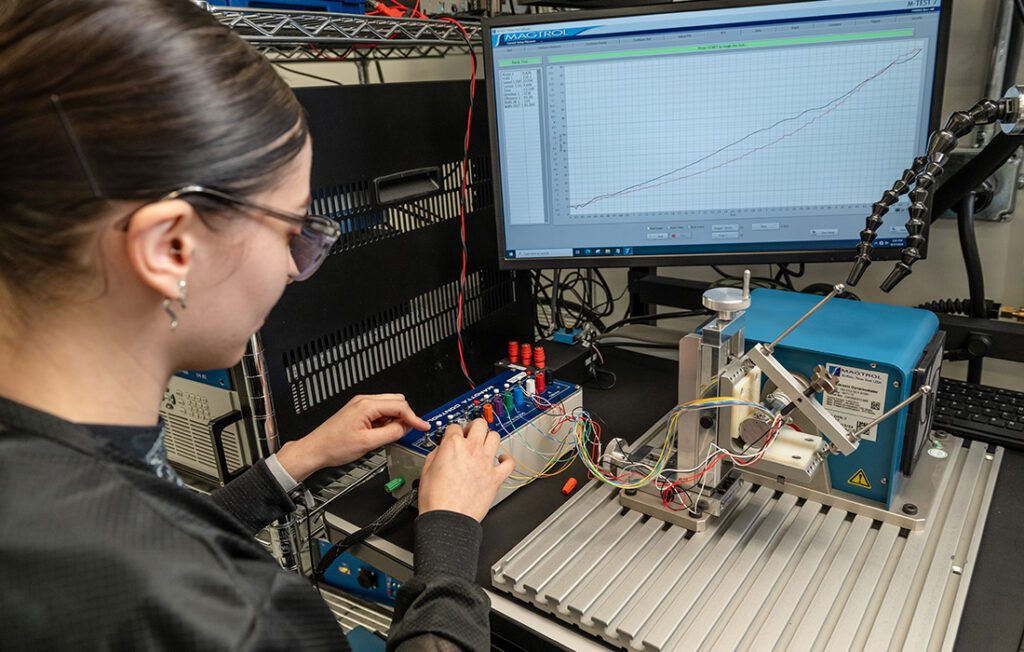

Rapid Prototyping

- Magnetic modeling and simulation

- Magnet cutting and magnetizing

- Wiring EDM

- 3D printing

- Laser cutting

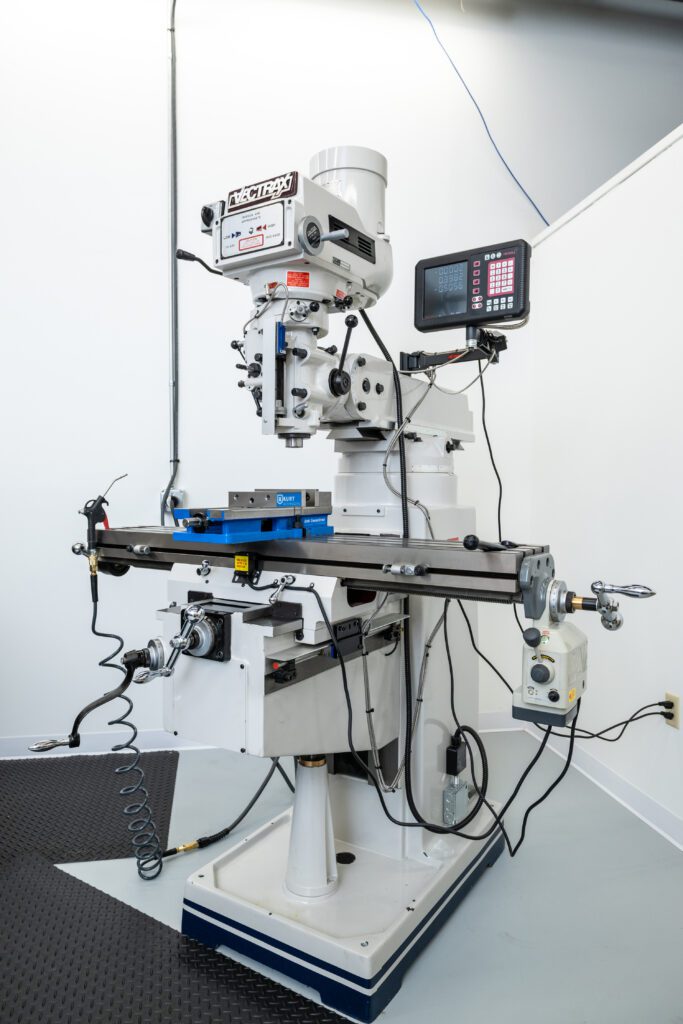

- CNC Mill/Lathe with Y-Axis/live tooling and sub-spindle

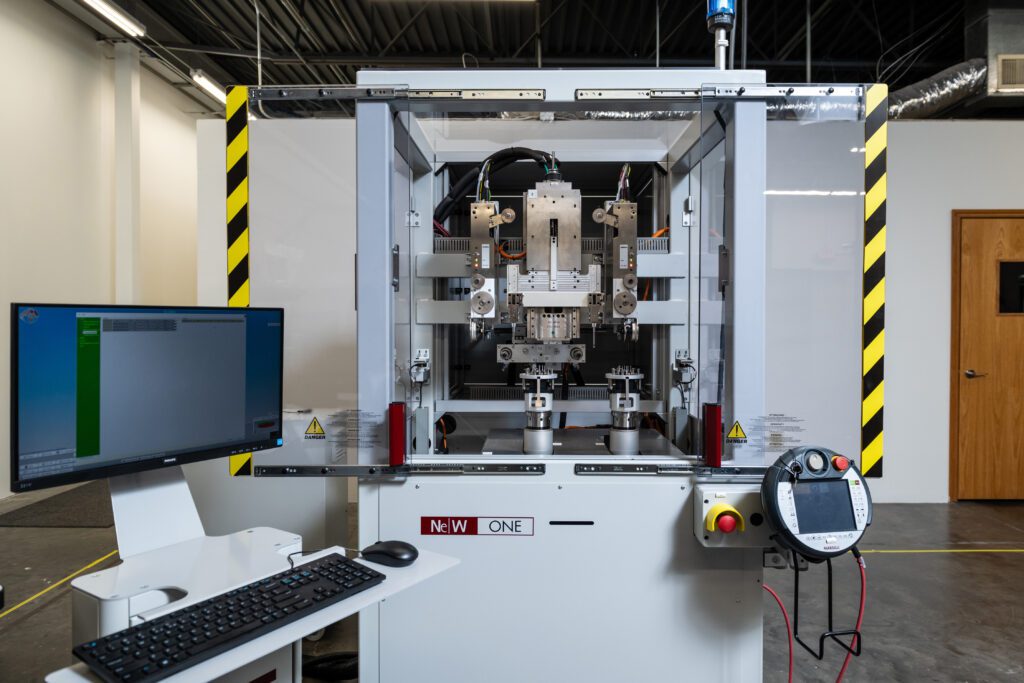

Motor Manufacturing

- Stack Assembly

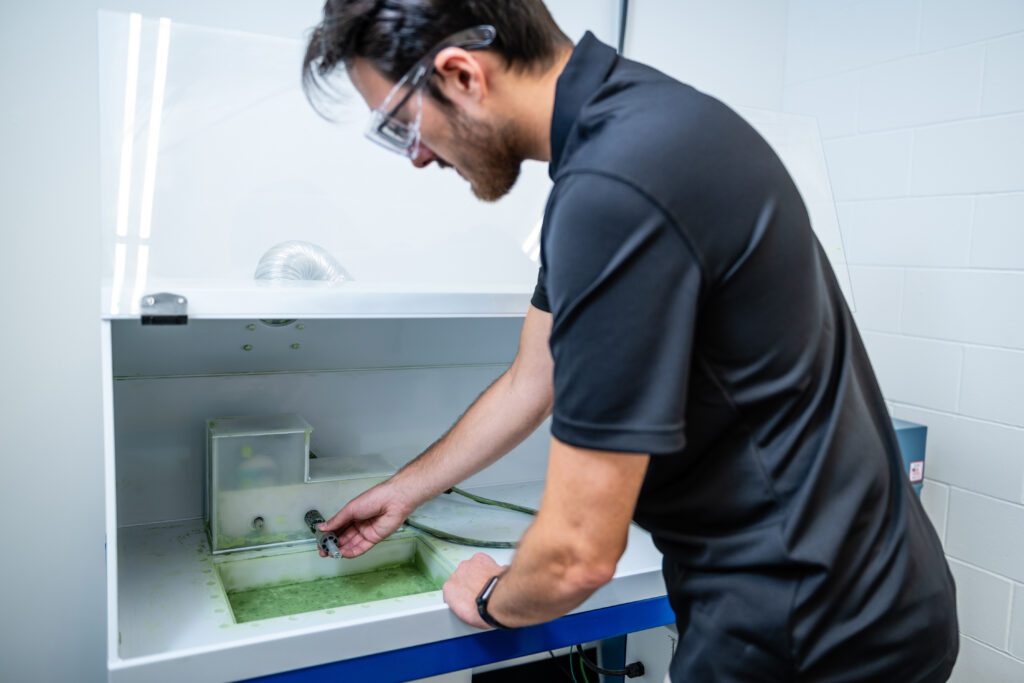

- Powder Coating

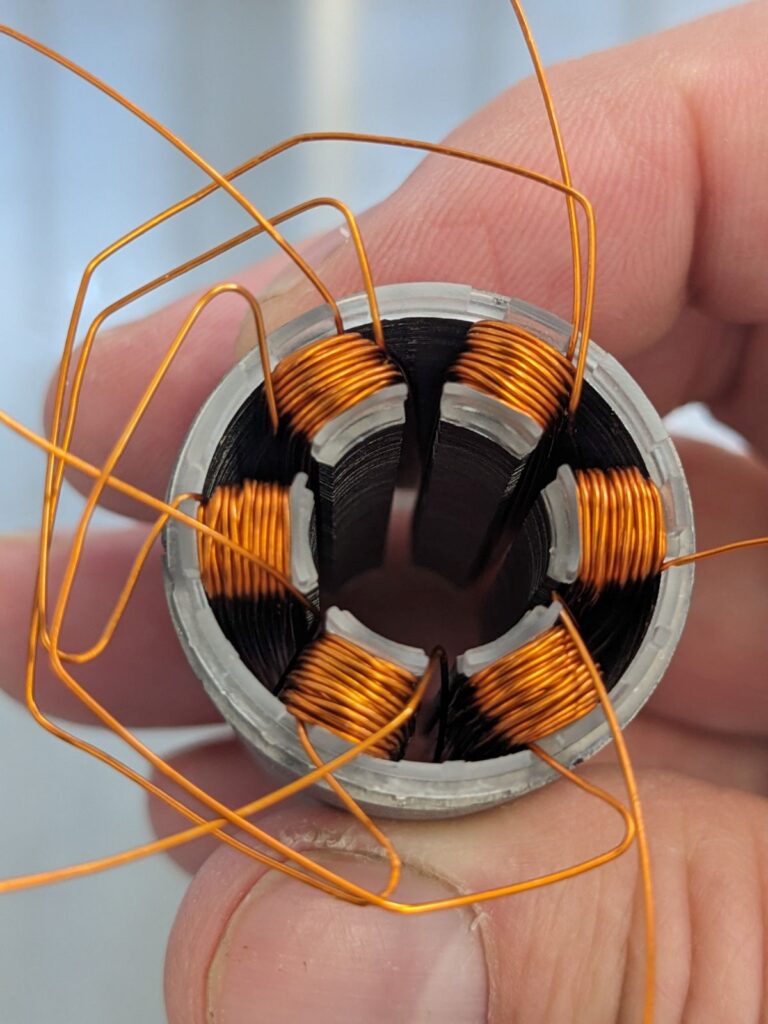

- Machine Winding

- Vacuum & Trickle Varnishing

- Magnet Assembly

- Laser marking & welding

Wide Range of Solutions

- Frameless & Fully Housed

- 0.42″ to 3.15″+ Diameters

- Fractional to 13 HP

- Rare Earth Magnets

- Hall Effect, Magnetic Encoder and Resolver interfaces

Brushless DC Motor Features

- Frameless and fully housed motors

- Lamination stack diameters from 0.42” to 3.0” and growing

- Fractional to 13HP

- Voltages up to 270 Vdc

- Higher performance Cobalt-iron alloy laminations as alternatives to Silicon steel

- Class H insulation

- Rare Earth magnets including both Samarium Cobalt and Neodymium alloys

- Motor commutation/sensor interfaces including Hall Effects, magnetic encoders and resolvers

Fill out the form below to download MotorFox_Datasheet