Flight-Qualified Flow Controls

With the intense pressures they operate under and their critical role in flight, valves used in spacecraft must meet incredibly strict tolerances. No matter whether it serves as a component of the vehicle’s engine, helps pressurize the crew cabin or feeds fuel to vital systems, each valve has to be extremely reliable and capable of delivering exceptional performance in extreme conditions.

Marotta Controls offers space valves with over 60 years of flight-proven heritage. Our pressurization and control valves played a critical role in the earliest days of manned spaceflight, from the fuel control valves on the Saturn rocket to propulsion systems for the Lunar Module ascent and descent engines.

With extensive experience and success in our space system technologies we are able to leverage our heritage and product portfolio and have evolved our qualified controls to meet the increasing requirements of Space applications. Today, our pressurization and propulsion controls provide reliable, cost-effective performance without compromise to commercial and military space control systems and spacecraft.

- Alpha

- Artemis

- Atlas

- CCTCap

- CST-100

- Delta II, IV

- Dream Chaser

- GOCE

- H2A/H2B

- ISS

- LauncherOne

- MetOp-SG

- New Glenn

- New Shepard

- SLS

- SpaceshipTwo

- Space Shuttle

- Talon-A

- Terran

- Chemical injection

- Engine controls

- Ground support equipment and systems

- Fuel purge lines

- Launch vehicles

- Pneumatic systems

- Pressurization systems

- Propellant feed systems

- Propulsion, including satellite propulsion

- Testing equipment

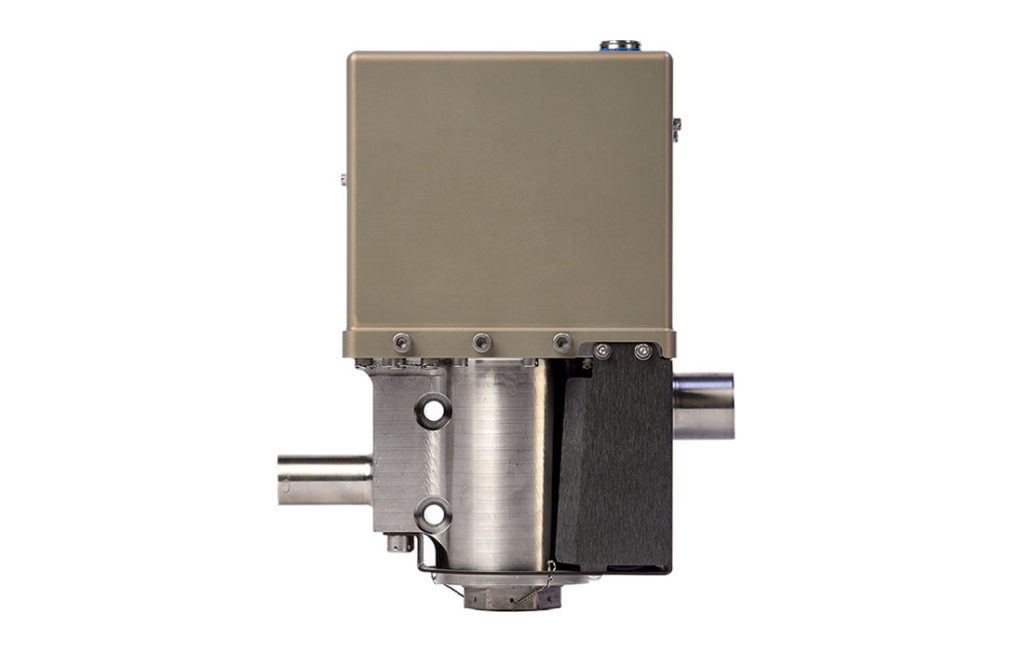

CoRe® Flow Controls

CoRe® Flow Controls series of solenoid valves is the optimal solution for complex commercial launch vehicle applications. CoRe combines proven high-performance and high reliability with affordability and availability.

- High volume production capability

- Reusable

- Wide-range of applicable systems

Satellite Propulsion

Our flight qualified engineered propulsion controls are compact, lightweight, use minimal power and are compatible with storable propellants used in electric propulsion and chemical propulsion feed systems.

- Latching and non-latching isolation valves

- Thruster valves

- Proportional control valves

Worldwide Standard in Solenoid Valves

With over 77 years of experience and hundreds of patented valves, we have the widest selection of solenoids as well as the expertise to design and manufacture solutions to meet your requirements.

- Balanced poppet design

- Customized solutions

- Space-flight qualified

Relief Valves

Advanced pressure relief valves for systems that contain gases and liquids in a variety of pneumatic, hydraulic and cryogenic applications.

- Compact & lightweight

- Pressure balanced poppet

- Narrow regulation band

Our space-qualified products for the above applications include flow controls, electronic pressure regulators, flight-qualified propulsion controls, solenoid controls, check valves, relief valves, piezo regulators, isolation valves, thruster valves and more.Our space-qualified products for the above applications include flow controls, electronic pressure regulators, flight-qualified propulsion controls, solenoid controls, check valves, relief valves, piezo regulators, isolation valves, thruster valves and more.

Pressure Control Mechanisms in Space Applications

Maintaining precision control over pressure in spacecraft cabins and fuel containers is crucial when operating in the vacuum of space. These valves have to be designed to meet extremely rigid requirements for performance and durability.

Another key consideration for a valve used in spacecraft is its weight. Every component that goes into a space vehicle has to be carefully engineered and manufactured to contribute as little mass as possible to the entire vehicle. Marotta Controls is proud to be able to say that our lineup of space valves continues to meet the exceptionally high standards of commercial space, just as they did in the earliest days of the American space program.

We offer an extensive line of services and support — all on-site under one roof. Our state-of-the-art facility enables us to design, develop, qualify, test and manufacture in one location, increasing our product quality and reliability while reducing lead times to protect program schedules. Our capabilities and expertise include design engineering, production engineering, development labs, assembly workstations, production cells, machine shop and a wide range of cutting-edge testing equipment.

With extensive accolades and credentials, we are proud to let our experience and success speak for itself. We:

- Hold more than 200 patents

- Are the only small business to win the coveted NASA George M. Low Award for Quality and Excellence — twice

- Emphasize quality control and customer services

- Hold quality approvals and certifications from numerous organizations, including S9100:D, ISO 9100-2015 (Revision D), AS9100, MIL-Q-9858A, MIL-I-45208 — and many, many more

Fill out the form below to download Marotta_Space_Brochure