State-of-the-Art Facility

Our vertically integrated operations ensure assembly and test procedures are streamlined to deliver the highest-quality, qualified control systems on-time. Our ability to design & develop customized aerospace testing equipment to meet stringent requirements in extreme environments enables us to deliver the highest performing solutions to our customers.

The majority of components/systems produced by Marotta Controls are “active control products” requiring 100% final acceptance testing. To achieve this requirement, Marotta Controls maintains complete on-site, high-performance materials testing capabilities.

Pneumatic Testing

- 40 pneumatic test benches

- 33 pneumatic test benches @ 6,000 psi

- 11 pneumatic test benches @ 15,000 psi

- Flow rates of 150 SCFM

- Grouped testing for up to 25,000 psi throughput

High Flow Testing

- Gaseous nitrogen high flow capability

- 2 piping systems up to 7,500 psi

- Up to 35,000 SCFM flow rate

- High compressor capacity and large nitrogen storage

Special Fluids

- Ammonia

- Freon

- Helium

- Hydraulic Oil

- Hydrogen

- Hydrogen Peroxide

- Inert Gas

- Isopropyl Alcohol

- Krypton

- LNG

- Nitrogen

- Oxygen

- RP-1

- Skydrol

- TEA-TEB

- Xenon

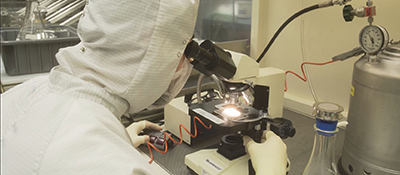

Clean Room

- 1,000 ft² Class 10,000/ISO 7 clean room on-site

- FED-STD-209

- 8 Flow Benches (Class 100) with flow hoods

- Nonvolatile Residue Analysis:

- Grade A Isopropyl alcohol filtered through 0.3 micron membrane, readable down to 0.01 mg

- DC-190 high temperature total organic carbon analyzer used with deionized water filtered through 0.2 micron membrane, readable to parts per million

Vibration Testing

- Air cooled electrodynamic shaker system

- Up to 4,000 lbs of force (lbf)

- Velocities up to 70 inches per second (ips)

- Payloads up to 1,000 lbs

- Electromechanical actuation and power systems testing

Thermal Altitude Testing

- Altitude simulation up to 120,000 ft

- Therrnal testing from -100ºF to 400ºF

- 15 thermal chambers on-site to perform tests simultaneously

- Vacuum testing to simulate up to 10-7 TORR

Acoustic Testing

- 1,600 ft² acoustic testing facility

- Structureborne & airborne noise testing

- Dual acoustic chambers for low and high pressure testing

- Test to less than 40 decibels for frequencies of 8 to 16,000 Hz

- Blowdown through 2″ & 4″ lines directly from tank to atmosphere

- Flow rate up to 270,000 SCFM at 6,300 psig

Hydraulic Testing

- 4 high pressure, high flow hydraulic test units on-site

- Flow rates of 25 GPM at 5,000 psig (MIL-H-83282 & 5606)

- Short duration pressures up to 10,000 psig of CTFE (MIL-H6083 or 5606 hydraulic fluid)

- Flow rates of 30 GPM at 6,000 psi Skydrol LD-4

- Flow ratess of 30 GPM at 1,500 psi of Lub Oil (MIL-PRF-23699)

Hydrostatic Testing

- Fluids testing up up to 60,000 psi

- Gaseous Nitrogen or helium testing up to 25,000 psi

- Walk-in proof chamber permits full operational control and visual assessment through bullet-proof glass viewing window

Welding

- Laser, electron beam & gas tungsten arc welding (GTAW) beam

- Certified nondestructive level 3 inspectors

Soldering

- Soldering in accordance with IPC-J-STD-001

- Space hardware soldered to IPC-A-610 & NASA STD-8739.3

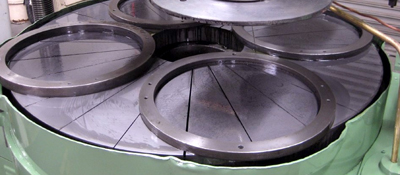

Lapping

- In-house capability to achieve ± 1 µ

- Flatness to ± 0.000001″