Solenoid Valves for In-Space Propulsion

Leveraging from over 77 years of experience in designing, developing and manufacturing solenoid valves for Aerospace systems, our engineering team developed a series of miniature flow controls for satellite propulsion systems.

Marotta’s miniature solenoid valves include latching and non-latching variants to meet the requirements of both high and low pressure systems found in satellite propulsion systems.

In the harsh environment of space, with the exacting requirements of mission-critical components, miniature solenoid valves from Marotta have proven time and again to be up to the task of precision flow control for numerous applications. In space applications, efficiency in size, weight and power usage are of paramount importance. Our mini solenoid valves meet these requirements, delivering reliable, robust construction in a compact package that can operate in low power scenarios.

Small solenoid valves are among the most important components in satellite and aerospace applications, better ensuring the continued proper operation of propulsion systems, XFCs, in-situ cleaning systems and more. As miniature solenoid valve manufacturers with decades of experience in high-profile space and satellite applications, we are ready to provide the valves you need. Learn more about our products below.

Fill out the form below to download White Paper – Adaptation of Miniature Latch Valve into Aeolus Oxygen Rated In Situ Cleaning System

MV602L

Latching Solenoid Valve

Composed of stainless steel, all welded construction and a plastic seat, the MV602L meets the demands for high reliability, tight leakage and quick response. MV602L miniature latching solenoid valves are designed for applications where power is limited or sensitive to high temperature operation.

- Xenon Feed Systems

- Micro-Propulsion

- Cold Gas Propulsion

Fill out the form below to download MV602L

MV602

High Pressure Non- Latching Solenoid Valve

The MV602 delivers maximum performance while requiring minimal power, physical envelope and weight. The highly optimized all-welded design in the MV602 miniature high-pressure solenoid valve can be used in a wide variety of applications, from Xenon Feed Systems to Gaseous Oxygen Systems and Micro Propulsion Systems.

- Response time < 10 milliseconds

- Minimal power draw

- Inlet and outlet filtration

Fill out the form below to download MV602

SPV187

Low Pressure Non- Latching Solenoid Valve

The flight-qualified SPV187 has been specifically developed for satellite in-space propulsion applications. With its low power requirement, minimal envelope and low mass, the SPV187 is ideal for all classes of platforms, from large telecoms to small science satellites.

- Electric propulsion thruster isolation

- Response time < 10 milliseconds

- Less than 30 grams

Fill out the form below to download SPV187

MV020

Solenoid Valve

The robust MV020’s leakage paths, moving parts, and weldments are minimized to provide a compact, robust design. Pressures and flow rates may be adjusted depending on specific applications

- Minimal power consumption

- Compatible with GHe, GN2, Xe, Ar, NTO and MMH

- Suitable for pressurization and propulsion systems

Fill out the form below to download MV0X0

Satellite Heritage

ADM-Aeolus

The MV602L was incorporated into the ADM-Aeolus mission, where it was adapted for use in the Aeolus Oxygen Rated In-Situ Cleaning System.

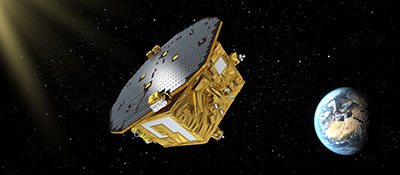

Lisa Pathfinder

The MV602L miniature solenoid’s latch technology is a key component of the Cold Gas Micro-Propulsion system on the LISA Pathfinder satellite.

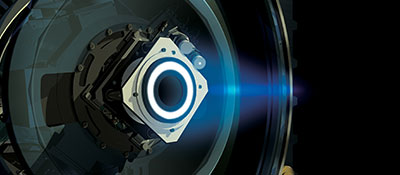

Smart-1

The SPV 187 was qualified on the Xenon Flow Controller (XFC) of the Snecma PPS1350 Hall Effect Thruster flown on the SMART-1 mission.

GOCE

SPV187 was a key component of the proportional XFC which provided the critical drag compensation capability that enabled the GOCE mission to exceed expectations

Alphasat

SPV187 was integrated into the in the Xenon Flow Controller of the Alphasat platform, Europe’s largest and most sophisticated telecom satellite.

Benefits of Our Miniature Solenoid Valves

We’re known throughout the industry for designing and manufacturing the most robust high- and low-pressure solenoid valves. We’re proud to be the manufacturer trusted by many of the world’s most demanding and exacting industries. Even in the most challenging environments and applications, our components deliver exceptional performance along with numerous advantages, including:

- Compact Design: We provide the smallest valves available on the market today. This means they are crucial for applications in which space may be limited. Despite their small size, these still can be counted on for industry-leading reliability and durability.

- Low Power Consumption: Because our valves are bistable, they require minimal power to open and close. This means they will minimize energy usage and generate relatively little heat compared to other valves.

- High-Pressure Compatibility: Their reliable performance under even the most demanding conditions makes these the absolute best miniature high-pressure solenoid valves found anywhere.

- Oxygen Safety: Our valves meet stringent oxygen compatibility requirements, making them the safest and most reliable choice for use in oxygen-rich environments.

- Cleanliness: These perform extremely well in applications in which contamination is a prime concern, thanks to designs and materials that meet some of the strictest cleanliness requirements.