Fill and drain valves are commonly found in spacecraft and satellites, where they serve to load and vent a wide range of propellants. They are designed to seal liquids or gases.

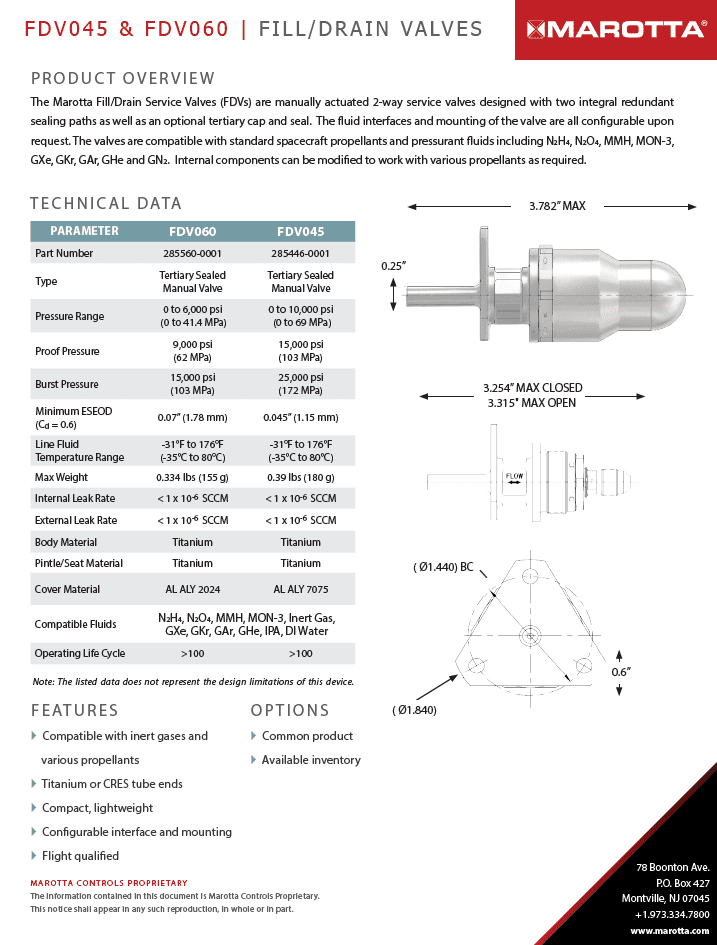

Marotta developed the FDV060 line of fill and drain valves to maintain ultra-tight leakage rates at a competitive cost. The valve utilizes a metal/ceramic main seat arrangement derived from crewed spaceflight applications, with redundant secondary seals and an optional tertiary cap and seal.

FDV060 features a load limiting design to increase allowable open/close cycles and simplify customer operation. The base design is easily configurable to customer needs – differing operating pressures, line fluids, and other specifications can all be met. Marotta leveraged our experience in higher volume commercial spaceflight valve production to offer these components at a highly competitive cost with reduced lead times.

- Helium

- Hydrogen

- Liquid Oxygen

- MMH

- MON3

- Nitrogen

- NTO

- RP-1

- Xenon

Fill & Drain Valves

- Internal/External Leakage rates <1E-6 SCCS GHe

- Lightweight, <.33 lbm

- Seat load limiting, robust design

- Configurable interface and mounting