Optimized, Scalable, Flexible Technology

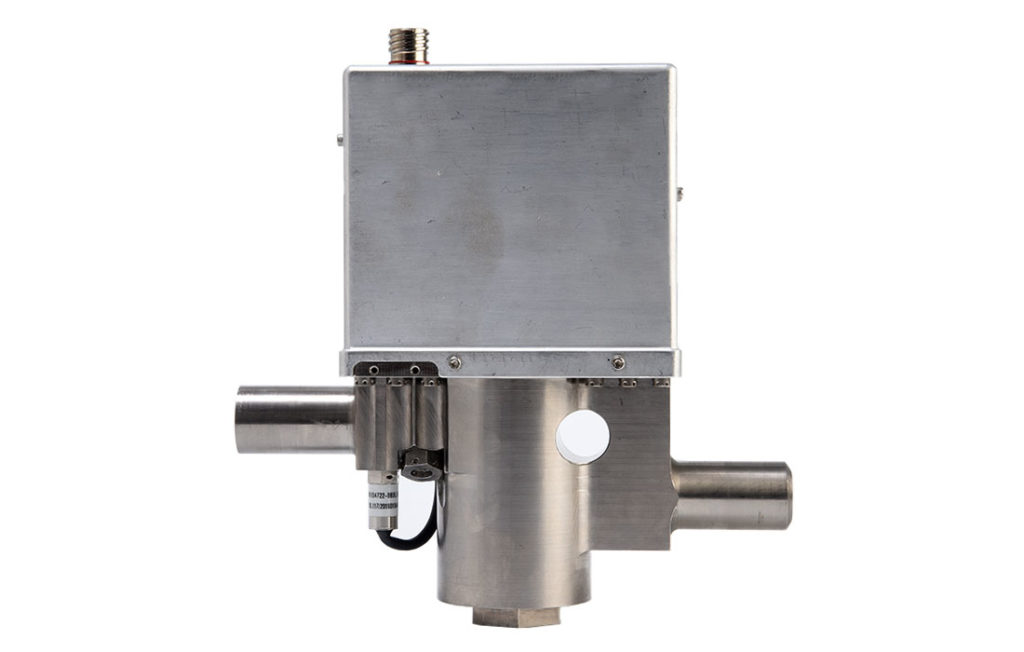

The unique multi-function characteristics of the piezo valve series means that just one valve can be used for isolation and regulation – which with conventional valves would require several different devices. Piezo valves offer precise control in a relatively small package, making them ideal for a wide range of high-performance situations. For example, some of the most important applications of piezoelectric valve actuators include aerospace equipment, precision instrumentation and medical technology.

With Marotta’s advanced piezo valve actuator technology, you can control flow parameters in real time and adjust the orifice size to meet your desired flow and pressure. The responsive piezoelectric actuator and integrated pressure transducers deliver state-of-the-art proportional control in a compact and lightweight package.

Fill out the form below to download MFV200

Piezoelectric Actuator Design Advantages

- Multi-functional operation: isolation and regulation

- <0.5 millisecond operation

- <1 milliamp power draw

- Proportional control

- Flexible applications

- Integrated inlet/outlet pressure transducers

- Integrated poppet displacement sensor

- Minimal heat generation

- Pressures up to 10,000 psig

- High dynamic control

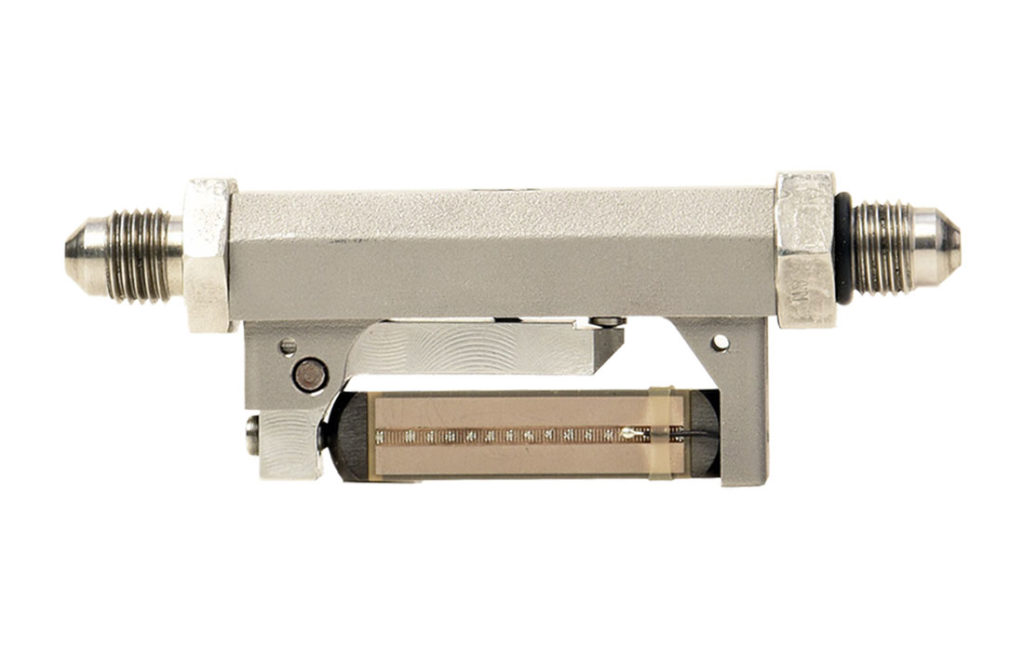

MFV020

The MFV020 is a unidirectional, piezo actuated direct acting 2-way proportional control valve with redundant sealing for all external leakage paths and is compatible with hypergolic fluids.

- GHe, NTO and MMH compatible

- Low power consumption

- Compact and lightweight

Fill out the form below to download MFV020

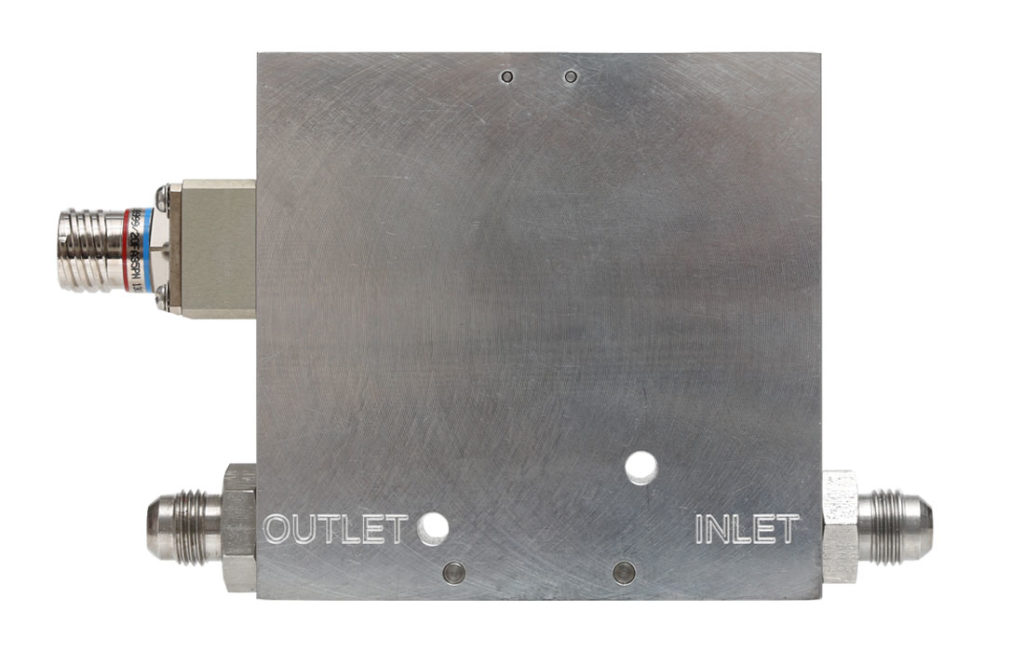

MFV200

The MFV200 piezo proportional valve is capable of measuring and controlling inlet and outlet pressures as well as valve orifice size in real time, eliminating system instabilities and improving reliability.

- Compatible with inert gases

- High reliability

- Balanced poppet

Fill out the form below to download MFV200

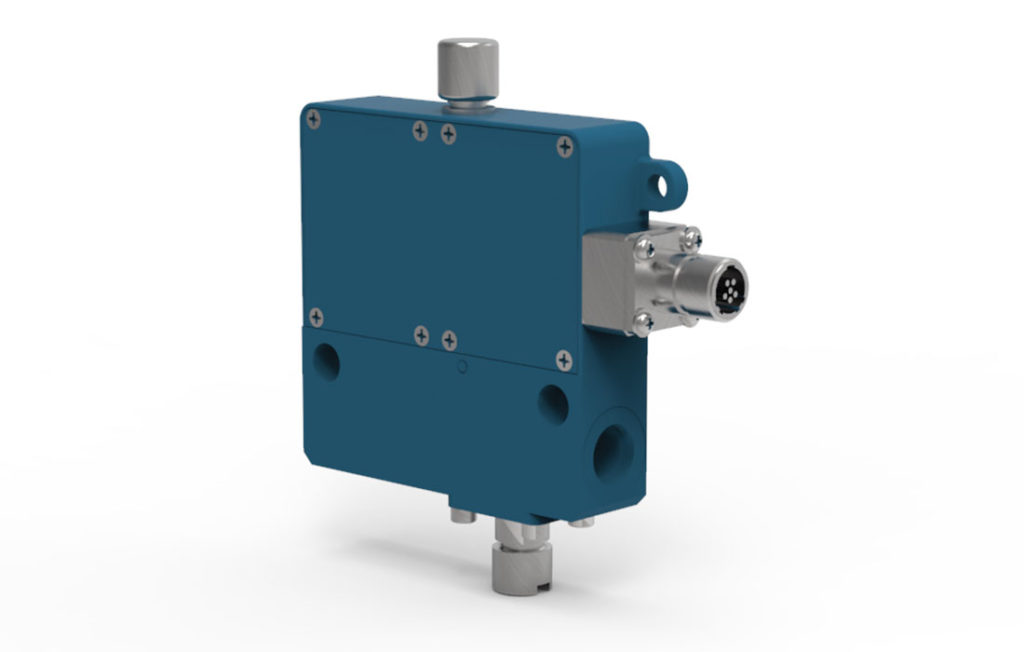

MFV400

Electronic pressure regulators provide precise control to propellant feed systems and are designed to handle high operating pressures and are qualified for use in dynamic spacecraft and missile environments.

- Up to 10,000 psi

- Triple modular redundant

- Scalable operation

Fill out the form below to download MFV400

Frequently Asked Questions

Our piezoelectric flow control technology gives these valves superior performance over traditional solenoid valves. They offer faster response times, lower power consumption and minimal heat generation. Their compact and lightweight design also helps conserve space and mass in aircraft, launch vehicle and naval platforms.

Our MFV series of valves offer a wide range of capabilities that make them ideally suited for numerous industries and environments:

MFV020 — offers redundant sealing and exceptional hypergolic fluid compatibility.

MFV200 — provides operators with real-time pressure management and higher system stability.

MFV400 — Capable of handling pressures of up to 10,000 psi and built with triple modular redundancy, this valve excels in extremely demanding conditions.

Piezotechnology offers numerous advantages over solenoids. For example, they consume minimal power, generate almost no heat and can be activated in less than a microsecond in many cases.

With integrated pressure transducers, our piezoelectric valves can provide real-time data. This is crucial for preventing overpressure scenarios in mission-critical applications such as in the aerospace and defense sectors. With detailed real-time insights into performance, these valves help ensure safe and predictable operation.

Our valves are designed with advanced sealing mechanisms and high-strength materials. They are capable of handling pressures of up to 10,000 psimakingmakes them ideal for use in aircraft to space propulsion systems.

These valves can work with hypergolic propellants including nitrogen tetroxide and monomethyl hydrazine. They also work with inert gases and non-reactive fluids commonly found in spacecraft and satellites. Their corrosion-resistant materials enable them to work within extreme environments.

Our valves offer a range of features to provide flexibility and scalability for different mission profiles. Among the many unique design elements that set them apart include integrated pressure transducers, poppet displacement sensors and redundant sealing for leakage prevention. These valves have been tested and verified to perform reliably even in extreme conditions, making them the choice for numerous high-performance industries.

Yes, our engineering team collaborates with clients to help them create tailored solutions that meet their specific needs. Whatever pressure ranges, power constraints or environmental conditions fit the use case, we have the expertise to create piezo valves that will deliver the proper performance.