Customers Gaining Major ROIs from State-of-the-Art Facility Centered on Advanced Airborne and Structure-borne Testing

MONTVILLE, N.J.—September 1, 2020—Marotta Controls, a rapidly growing aerospace and defense supplier based in New Jersey, today released additional information about its state-of-the-art acoustic testing facility first introduced in May. Already in use, the facility is the nation’s most sophisticated resource for airborne and structure-borne noise analysis of various technologies sensitive to sound affecting end application performance . Customers gain numerous benefits ranging from project cost reductions to faster system diagnostics and hardware adjustments, all while meeting MIL-STD-740 standards.

Marotta’s new capabilities span a freestanding 1,600 ft2 building that houses dual sound chambers—one dedicated to low-pressure simulation and the other dedicated to high-pressure simulation. This space accommodates low- and high-pressure airborne testing as well as low-pressure structure-borne testing. An additional 970 ft2 in the company’s main building accommodate high-pressure structure-borne testing .

The acoustic chambers support noise ratings of less than 40 decibels for frequencies ranging from 8 to 16,000 Hz. Leveraging multiple nitrogen tanks networked throughout the facility, blow down testing is accomplished via 1,989+ ft3 of nitrogen storage at 6,000 psi and 1,600+ ft3 of nitrogen storage at 800 psi . Maximum pressure and flow ranges from 650 PSIG (up to 28,000 SCFM) to 6,300 PSIG (up to 270,000 SCFM). Note that structure-borne testing is currently able to reach the maximum pressure and flow limits whereas airborne testing currently reaches 800 psi (up to 28,000 SCFM) and is expected to reach maximum limits by the end of the year. Marotta is also in the process of installing additional tanks that will allow for longer test durations.

Lastly, to complete the testing process, Marotta has developed a custom, advanced analytics software . The sound data capture system swiftly collects, compiles, analyzes and reports on data in easy-to-read formats designed for customer and internal use.

“Until now, the market offered only one testing facility spec’d to our basic needs, which was based on the West Coast,” said Brian Fly, Vice President, Marine Systems, Marotta . “However, customer hardware solutions are becoming more complex, requiring more advanced testing techniques. As is our nature, we felt it necessary to take lessons learned thus far and define, then build our own facility. This is our way of ensuring the highest quality materials, systems, and tools are used to create the highest quality testing labs. The cost-benefit analysis clearly indicated major value propositions not just for our customers, but for our own teams as well. By housing acoustic testing under our own roof, we’re freeing our engineers to do what they do best—solving customer challenges through innovation.”

Noteworthy returns on investment (ROIs) include a 30 percent reduction in project cost as well as an up to 25 percent reduction in project lead times. The ROIs come from multiple process efficiencies partly enabled by the facility’s location. Prior to Marotta’s construction effort, the company relied on a third-party lab situated in California. The cross-country locale added time and cost to projects due to limited timely access to expert engineers, flying experts out for on-site diagnostics, product disassembly and reassembly, shipping, machine shop access, and more.

About Marotta Controls

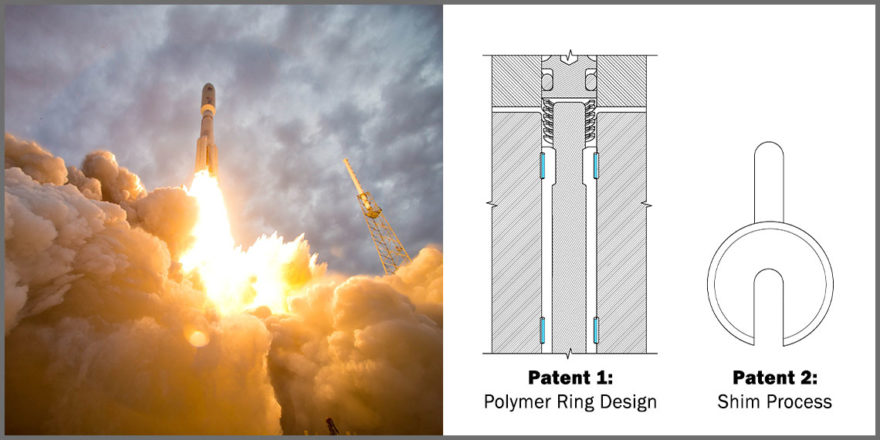

Founded in 1943, Marotta Controls is a fully-integrated solutions provider which designs, develops, qualifies and manufactures innovative systems and sub-systems for the aerospace and defense sectors. Our portfolio includes pressure, power, motion, fluid, and electronic controls for weapon systems, shipboard and sub-sea applications, satellites, launch vehicles, and aircraft systems. With over 200 patents, Marotta Controls continues to build on its legacy as a highly respected, family-owned small business based in the state of New Jersey. Twitter: @marottacontrols LinkedIn: Marotta Controls, Inc.

Contact:

Heather Ailara | 211 Communications | 973.567.6040 | [email protected]

Katee Glass | Marotta Controls | [email protected]