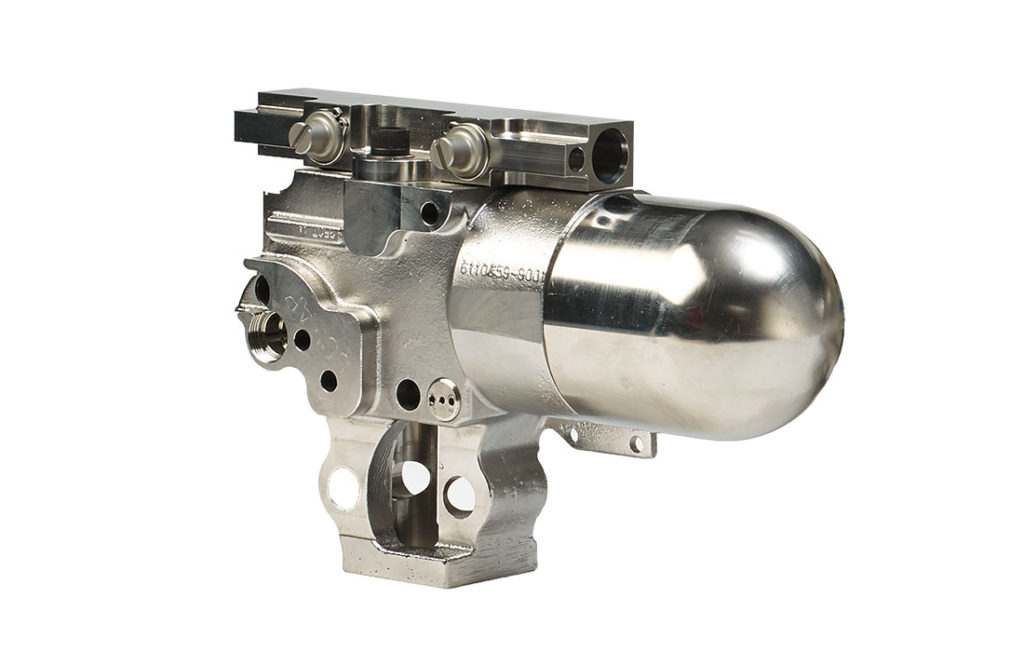

Pneumatic Firing Valves

Pure Power. Consistent Shots.

Our high-performance pneumatic firing/ ejection valve technology powers next-generation smartbombs. These firing/ejection valves use high-pressure air to release the weapon. As a key component of the Small Diameter Bomb program, Marotta Controls designed, developed, qualified and supplied these firing/ ejection valve systems to power the SDB’s next-generation stores ejection racks.

Marotta’s Pneumatic Ejection Valve Manifold Assembly system consists of a firing valve, integral accumulator, relief valve, manual vent valve, integrated latch points, pitch control valve and dual outlet ports all in a high performance package.

Fill out the form below to download SPV752

Features

- Integral latch actuator

- Fast Response time <30 milliseconds

- High flow design

- Safety interlocks

- Integral high pressure accumulator

- High strength-to-weight materials

- Precision inverted relief valve

- No pyrotechnic charges

- Precision inverted relief valve

- Qualified MIL-STD-810

Capability Impact

- Higher ejection force allows release of stores at higher speeds

- Pneumatic power provides consistent shot-to-shot ejection profiles

Efficiency Impact

- Clean air powers the rack, eliminating the need for frequent cleaning which is a common problem with pyrotechnic charges

- Cost efficient – because it’s reusable, there’s no need to replace costly squibs after each mission

- Reduces logistics problems by eliminating the need to acquire and store pyrotechnic devices