Contaminant-Tolerant Fluid Controls

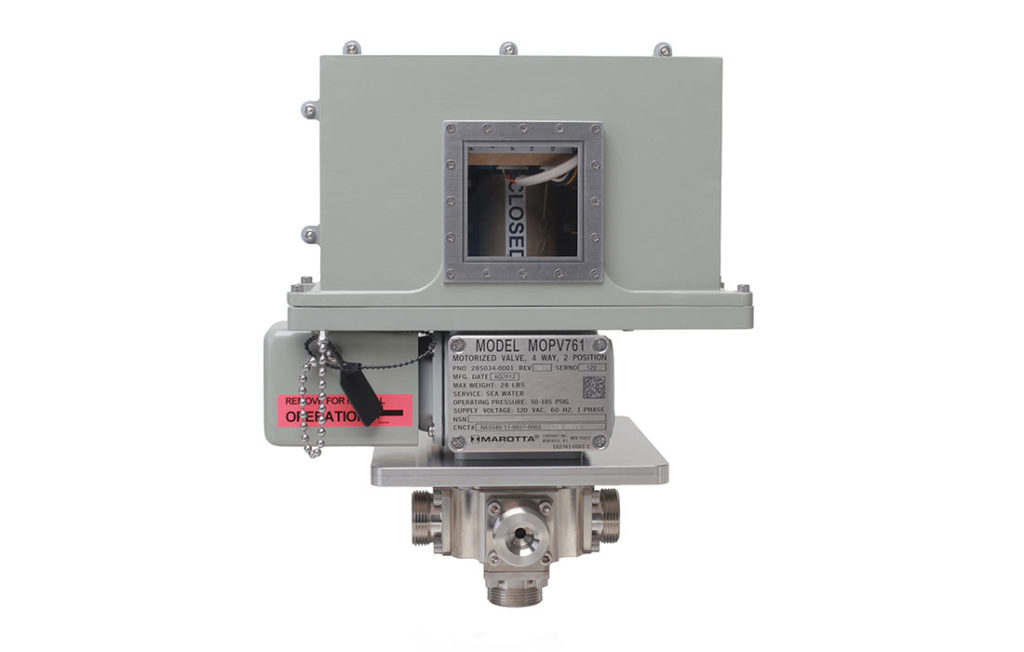

The qualified Motor Operated Pilot Valve series, integrates advanced materials and electronics to reduce weight, life cycle costs, and corrosion sensitivity of shipboard fluid control systems. Using a self-contained seawater valve, (also available in 2-, 3- way), this 4-way, 2-position pilot control valve provides two control functions, as a four-port master MOPV and a three-port service MOPV.

This series also uses a modular design which enables easy maintenance, both on ship and in depot. Each module can be easily replaced aboard ship without disturbing the remaining assemblies.

To learn more about this or any other solutions we provide, get in touch with us today.

Fill out the form below to download MOPV

Fill out the form below to download MOPV Article

MOPV761

A four-port master MOPV is used to initiate aqueous film forming foam (AFFF) concentrate flow and fire-main flow for mixing and disbursement to AFFF systems aboard the Navy fleet. The three-port MOPV will serve as the local disbursement valve for either fire-main flow or the AFFF mixture.

Responding to control signals, the motor operated actuator opens and closes the valve by turning a rotor within the valve body. The rotor, which contains the valve’s fluid control passages, rotates 90 degrees to open or close. In the event of a signal or power loss, the rotor is easily actuated manually by an integrated hand crank.

Fill out the form below to download MOPV

Design Features

- Visual and electrical position indicator

- Solid-state controls on single, replaceable circuit board

- Low-cost maintenance and logistics

- Ability to operate in any physical orientation

- Reliable mechanical design

- Service interval of 25 years

- Long maintenance interval

- Robust design

- Available in 2-, 3-, and 4-way

- Manual override

- Seawater corrosion resistant

- Modular, easy installation